Quality Control

OEM-level Quality Control for Aftermarket Reliability

At CHIHON MACHINERY, quality isn't just a promise – it's the core of everything we do. For over 39 years, we've been committed to delivering brake components that don’t just meet industry standards but exceed them. Every part we produce is a result of precise craftsmanship, advanced technology, and a relentless focus on quality.

Our Quality Control Process: Excellence in Every Step

1. Rigorous Raw Material Selection

Our quality journey begins with the careful selection of premium materials. We use FC250 cast iron (also known as Grade 250 Cast Iron, GG25, or Class 250 Cast Iron) – a material known for its exceptional strength, durability, and performance under stress. We don’t just accept materials at face value – every batch is tested for durability and consistency, ensuring it’s ready to perform under demanding conditions.

2. Precision Machining & Balancing

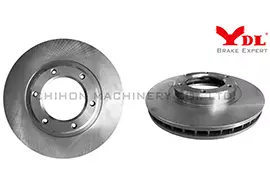

Our commitment to precision starts with state-of-the-art machining technology. Every component is manufactured to exact specifications, and we employ advanced balancing techniques to ensure each part performs safely and reliably. Whether it’s for OEM customers or the aftermarket, our precision ensures optimal performance, safety, and longevity.

3. Advanced Surface Finishing

To provide brake components that stand the test of time, we utilize cutting-edge surface finishing technologies. Our process not only enhances corrosion resistance and wear properties but also optimizes friction control. The result? A product that can withstand the harshest environments and provide dependable performance throughout its lifespan.

4. Comprehensive Final Inspections

We don’t just rely on automated machines – our final inspection is a hands-on process, conducted by skilled technicians who understand the importance of every detail. Each product undergoes rigorous testing for:

- Dimensional accuracy: to ensure every component fits perfectly.

- Stress testing: simulating real-world conditions to verify durability.

- Consistency across batches: every product we ship is as reliable as the last.

We don't just meet the standards – we set them.

Third-Party Testing with GOSHEN Industries INC.

We go beyond our in-house testing by partnering with GOSHEN Industries INC., a trusted third-party testing facility. Through their independent lab tests, we validate that our brake components meet global safety and performance standards. These rigorous tests ensure that our products are ready for the real world.

Why Choose Us?

When you choose CHIHON MACHINERY, you’re not just choosing a manufacturer – you’re partnering with a company that has built a legacy of excellence in the brake components industry. Our attention to detail, innovative processes, and commitment to quality ensure that every product we deliver is reliable, high-performing, and safe.

With ISO certifications, OEM-specific approvals, and our unmatched quality control system, we guarantee that your products will not only meet but exceed customer expectations.

Your Trusted Partner in Brake Safety

We don’t just supply parts – we deliver peace of mind. Trust CHIHON for your brake components, and experience the difference that uncompromising quality makes.

LAB Test

The SAE-J2522 lab test based on AK-Master Standard testing coefficient of friction in lab. The result:

1) with normal brake pad: µop(av) 0.405.

2) with race brake pad: µop(av) 0.489.

* Normal Coefficient of Friction > µop 0.18