Manufacturing

Brake Disc Rotor Manufactured To Match Original Disc Brake Requirements

Chihon (YDL) basic processes in the production of brake disc rotor for automobiles component parts. The basic process is divided into 4 steps, includes:

1. Purchasing raw materials (R&D tooling test, report inspection, mass product casting, material and hardness testing),

2. Scheduling, programming and machining (including customized design such as slotted and drilled),

3. Measurement and inspection,

4. Packaging and shipment.

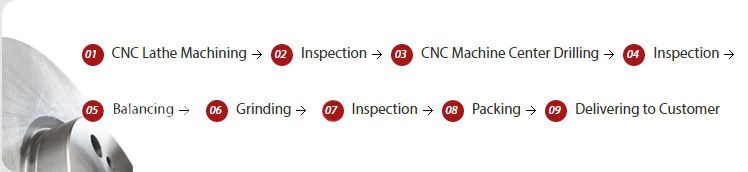

Manufacturing Steps:

Material of disc brake rotors

In terms of materials, we select FC250 (US: G3000; CN: HT250) in accordance with the standards of the OE manufacture, and each batch of materials has chemical analysis and physical analysis report. Chemical analysis has the specification and content of elements to determine the quality of good or bad. The physical analysis is divided into two parts: 1) tensile test (tensile strength kg/mm² above 25 in the specification) and hardness test (Brinell HB 170-240): 2) organization test (graphite & Al Qaeda Ferrite below 5%).

Machines Photo

- CNC Horizontal Lathe <V26>. Using a lathe to machine convex side, and the size tolerance compliance with the OE requirement.

- CNC Vertical Lathe <V300>. Using a lathe to machine concave side, and the size tolerance compliance with the OE requirement.

- Vertical Milling Machine <TMV-760>. Use milling machine to machining center holes compliance with OE standard.

- Balancing Machine. Use balancing machine to measure and qualify balancing tolerance within 100g.

- Grinding Machine. Use to grinding the braking surface and keep DTV tolerance within 0.02mm/0.005um.

- Milling machine

- Milling machine

- Use to customized the design, upgrade the braking.